Can 3D Printers Help Build an Ice Cream Shop? A House? Local Startup Aims to Find Out

This article was in the June 30th, 2021 Herald and News

Written By: Rick Childress

William Weissmeyer is running an experiment in downtown Klamath Falls.

Two large metal shipping containers sit on the lot outside Vioweiss, Weissmeyer’s East Main Street tech startup. The nondescript appearance of the containers belie their planned destiny.

One of the containers is in the early stages of becoming Klamath Falls’ next local ice cream shop Weissmeyer is hoping the other will be a low-cost, two-story home.

Weissmeyer plans to use 3D printing to manufacture the signage, walls, insulation and other parts necessary to transform humble shipping containers into livable, sellable and sustainable spaces.

Dubbed “The Flavor Container,” the soon-to-be ice cream shop will be a proof of concept and an on-site experiment.

“The idea here was: Let’s see if we can do a micro-business on the lot, while proving out the concept of having 3D-printed walls,” Weissmeyer said. “Because I want the general public to get exposed to this stuff.”

A ‘serial entrepreneur’

As Weissmeyer opened the metal doors of The Flavor Container one morning in June, he described himself as a “serial entrepreneur.”

For about nine years, Weissmeyer said he worked in leadership positions in various technology companies around Seattle and Portland. But in 2017, Weissmeyer decided it was time to exit his desk job.

“When you work in corporate America, you’re basically a nine-to-five specialist in something,” Weissmeyer said. “It wasn’t giving me the opportunity to learn stuff. That’s when it kind of dawned on me and that’s when I started seriously looking at this technology.”

The cost of 3D printing has declined in recent years as supplies and the printers themselves have become cheaper, Weissmeyer said.

The printing process begins first in the mind of the designer, who mocks up whatever object they want printed in a computer design software. The design is sent to the printer which builds the object, layer by layer, with extruded hot plastic until the planned three-dimensional structure becomes reality.

“It’s really an amazing technology for manufacturing,” said Jake Sarnecky, a recent Oregon Tech mathematics graduate who works and apprentices at Vioweiss. I don’t think there’s anything that compares to it.”

Weissmeyer started Vioweiss with $20,000 in 2018. He started by printing and selling small accessories and small parts for instruments. Online, Vioweiss products are able to out-compete Chinese-manufactured plastics, enabling Weissmeyer to fund and grow the business.

“Then I moved the business here in 2019,” Weissmeyer said. “Because in Seattle, a building like this costs $3 million. I don’t have a silver spoon, right, and there’s good educational institutions here and I think Klamath is very business friendly to operate in.”

Transitioning to something bigger

Vioweiss has recently earned two grants from Klamath County — $15,000 to explore building development and another $10,000 for the ice cream business.

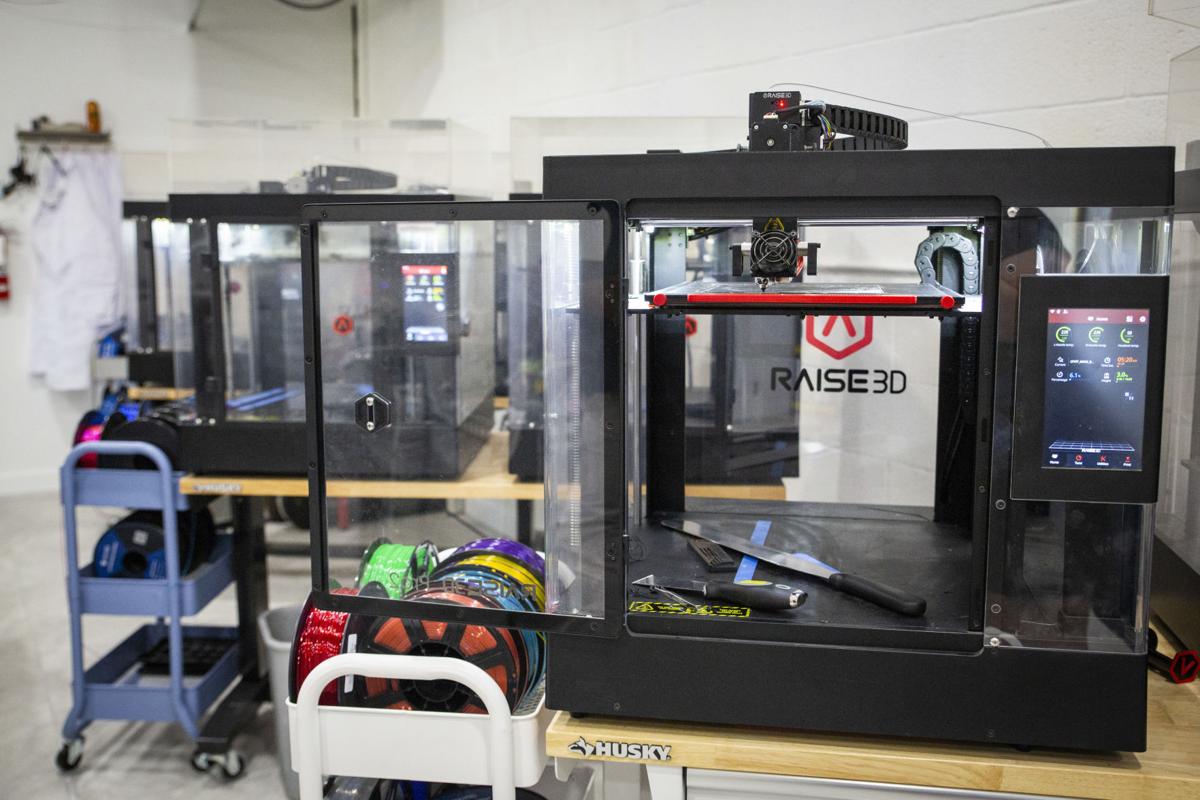

At the company’s East Main Street research and development facility, Weissmeyer has a small army of commercial-grade 3D printers and one substantially larger one that is soon to come online.

The larger printer, which is nearly as tall as Weissmeyer, enables Vioweiss to transition into printing larger components like those needed to create an ice cream shop or future home.

The outside of the Flavor Container currently looks like any other shipping container, but Weissmeyer envisions it having large, colorful, 3D-printed tiles covering the exterior and a large service window cut out on one side — similar to a food truck.

Weissmeyer said putting in a traditional window would cost close to $1,000 and would require nearly 64 pieces. By 3D printing the frame, Weissmeyer estimated that he can cut down the cost to around $250 and the whole window would be pared down to just three pieces — two frames and the glass itself.

With the Flavor Container on the lot, Weissmeyer said they can watch how people interact with some of the design elements and see “if they like certain things, if some design elements don’t work. So this is really a pretty big experiment for us to be able to do this.”

Weissmeyer is planning on transferring the knowledge gained from the Flavor Container into his next project: A two-story home made with retrofitted shipping containers and 3D-printed walls composed of plastic from recycled water bottles.

“Housing is super expensive. Quality of it is not always great,” Weissmeyer said. “There’s a lot of maintenance issues associated with traditional building.”

The home — made with two shipping containers — will be built for a single person. The containers are “fire proof” and “earthquake proof,” Weissmeyer said. The market he’s trying to target are 18-to-40-year-olds who might be sick of living with roommates or renting.

“What am I getting for 1,000 or 600 bucks a month? Why don’t I buy?” Weissmeyer said. “I would like to be able to turn around, say, ‘OK, you can own your own home for $40-60,000.’”Viowiess apprentice and recent OIT graduate Jake Sarnecky feeds filament into a 3D printer at the Viowiess Co. location in Klamath Falls on Tuesday.

‘Everyone should be able to afford their own home’

The “complete solution” is years away, Weissmeyer said. By the end of this year, being able to make exterior insulation, framing for windows and doors and know that they work would be great progress.

If they find that those components work, then Vioweiss could turn around and start selling those individually to start drumming up the funding for the company’s future projects.

“I’m 38. When I was 24, I didn’t have $100,000 in my pocket, and I had student debt, you know,” Weissmeyer said. “It’s part of the American dream that everyone should be able to afford their own home, and it shouldn’t be a tent or a structure that’s only going to last five years either. So that’s kind of the vision for what we’re doing here.”

The crew right now is small, including Weissmeyer, Sarnecky and those they are training to run the ice cream shop.

The Flavor Container will be open for business this summer. It’s already on Yelp.

In mid-June, Weissmeyer was working through permits with the health department. A menu is already posted online and they’re in the process of training the shop’s first two employees on how to use the six ice cream machines.

Over the summer, they’re hoping to be open on Sundays so folks can check out their progress and grab a scoop of ice cream or sorbet.